Screen printing is a printing technique that uses a mesh to support an ink-blocking stencil. The stencil forms open areas of mesh that transfer ink as a solid image onto a substrate, such as paper or fabric.

Choose the Screen and Fabric

Screen printing is a great way to print multiple colors on a single piece of fabric. You will need to choose the screen and fabric carefully to get the best results.

The screen should be large enough to print the image on the fabric, but small enough that the fabric doesn’t extend beyond the edges of the screen. Most articles of clothing will handle being printed on with multiple colors, especially with natural fibers that will not tear or run when the squeegee is pulled across the screen to put the ink on the clothing. The screens being used should have plenty of strength to be used with a single design.

Screen printing is a process of printing text, images, or designs onto fabric using a screen. Screen printing is often used for clothing and other items because it is a fast and affordable way to make large quantities of products.

To screen print multiple colors, you will need screens that have plenty of strength to be used with a single design. You will also need a printer that can print in multiple colors.

While natural fibers in clothing are most suited to retain the ink being transferred, the “man-made” fabrics are also able to be printed on. These fabrics sometimes require more care and might be a bit more fragile. This article is more general in nature so the various material options will be discussed more in other articles.

Mix the Ink

Inks can be purchased in a wide range of colors to be used in a screen-printer. Then by mixing the colors there can be wide variations of the primary and secondary colors. Just like when we were in elementary school painting with watercolors, we can make the red, green, and blue of the spectrum appear as new colors.

There are different types of ink that are used in screen printing. There are discharge inks, plastisol inks, and water-based inks. Each of these types has some advantages and some drawbacks. The most common inks used today are plastisol and water-based.

One of the most important things to consider when screen-printing clothing is what the material feels like when the prints are delivered. This is often referred to as the “hand”. Does it feel like it can be pulled off with just a bit of work? Will it feel like a plastic sign that has been plastered across the chest of the wearer?

This is the art and science of using these inks and of screen printing. Water-based inks are best suited for cotton fabrics. It can be a cotton blend, but it should be a majority of cotton. With water-based inks, there is a better feel when the inks are absorbed into the material, which is a strength of using this combination of water-based ink and cotton.

There are however drawbacks to using water-based inks. They can dry out on the screen causing major issues with future prints. They can also sometimes be mixed too thin and become runny. Sometimes the water-based ink will be too transparent and not be visible on the clothing. With experience and practice, most issues can be resolved but this is a difficult option when beginning to screen print.

Plastisol ink is the choice of a lot of commercial screen printers. It is a bit easier to use. It doesn’t dry out as quickly as the water-based ink sometimes does. This is because it requires heat to dry completely. (As a side note the water-based ink requires heat also but that is to make it set and bond with the fabric.)

There are some brands and types of ink that will mix better with other colors. The end results will determine what will be the “shop” favorite, and that will come after practice and experience.

Apply the Ink to the Screen

The ink for screen printing is a thick paste that generally comes in a bucket, a jar, or sometimes a “tub”, depending on the quantity that is purchased. This ink is applied to the screen with a scoop or it is poured from the container.

Pour the ink at one end of the screen. The amount that is put on the screen should be enough to cover the screen when it is pulled, or pushed, with a squeegee. In my workflow, I pour a bead of ink about two fingers thick across the short top side of the screen frame.

This ink is pulled across the image of the screen in as close to a single motion as possible. This action is called “flooding” the screen.

This allows the ink to flood across the image in the emulsion so that the openings are filled with ink. The next push of the ink is actually the push that forces the ink through openings and onto the fabric of the item being printed.

A good screen printing machine will handle the movements of the ink through the screen without moving it. The amount of pressure that is required will come with time, practice, and experience. I could tell you “apply 14 pounds of pressure to the squeegee” but that is difficult to gauge. After printing some items (fabric, paper, ceramics, or wood) you will begin to develop some muscle memory for printing. It will then become second nature and the amount of pressure required will become second nature.

Print the Image

This same process of applying the ink will be required for each of the colors needed for the image. The colors will each have a screen of their own. This can generate a high-quality screen that will be more in line with what a customer is needing.

There are millions of colors but using the additive primary color spectrum the only true colors are red, green, and blue. Using the secondary colors of cyan, magenta, and yellow (subtractive colors) a printer can make most of the colors of the spectrum. A simple four-color printer will make beautiful color prints when properly registered.

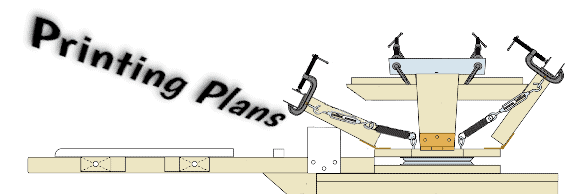

The printer that is available on this site works great for multi-color and full-color screen prints. The full kit is the best option for the most reliable and precise color prints available for the home screen-printer. Our screen printer kit has micro-registration features to provide absolute color alignment as well as easy adjustments for each color.

Conclusion: Screen printing is a great way to create multi-colored prints. By following these simple steps, you can create your own screen prints!